Have you ever been working on a project with a drill bit and noticed that it wasn’t performing as well as expected? If so, you may be wondering, can drill bits be sharpened? After all, sharpening blades has been done for centuries – why not bits too?

Drill bits are an essential tool for many DIY projects. Oftentimes, they can become dull and need to be replaced. But that doesn’t always have to be the case. In some situations, it may be possible to sharpen your drill bit and keep it in service for a longer period of time.

Keep reading to learn more about how to sharpen drill bits and some tips to help keep them sharp.

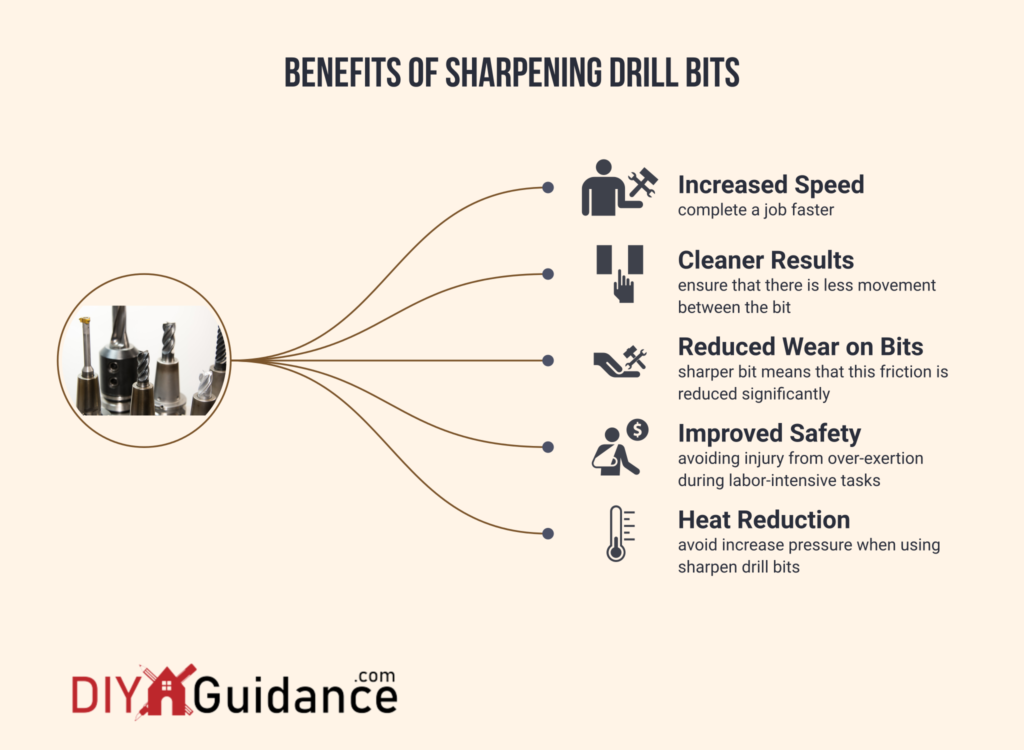

Benefits Of Sharpening Drill Bits

Before we get into the details of how to sharpen drill bits, it’s important to understand the benefits. Most people are aware that blades can be sharpened, but what about drill bits?

Sharpening a drill bit can be beneficial for multiple reasons. Here is a look at some of the advantages of keeping a well-sharpened drill bit:

✅Increased Speed

Sharpened drill bits can complete a job faster than dull ones. This is especially true with hard materials like metals since the tip won’t have to be pushed through as much material. The increased speed will save time and energy when working on projects.

✅Cleaner Results

Having sharp edges on the cutting surfaces will ensure that there is less movement between the bit and the material being worked on. As such, there will be less chance for splintering or chipping along the edges of whatever is being drilled into. The result will be cleaner holes with crisp edges.

✅Reduced Wear on Bits

With each rotation that happens while drilling, duller bits cause more friction against what they are cutting into, which increases wear on them. A sharper bit means that this friction is reduced significantly, leading to longer life spans for tools and more efficiency in work productivity overall.

✅Improved Safety

When using a newer or sharper bit, users don’t have to use as much force to get their desired results. This can be especially helpful in regards to avoiding injury from over-exertion during labor-intensive tasks such as drilling metal pieces or large wooden boards together.

✅Heat Reduction

Users typically increase their pressure when drilling with a dull bit to make up for the bit’s diminished efficiency. This leads to the drill bit getting too hot, which in turn causes it to dull faster.

This problem can be avoided along with the potential for drill damage by maintaining sharp drill bits. When a tool overheats, it might produce micro cracks and break down.

Different Types of Drill Bits Materials and Their Suitability for Sharpening

While all drill bits can provide a basic level of sharpening, not all of them are suitable for more complex tasks. Here are some of the most common drill bit materials and their suitability for sharpening:

📍High Speed Steel (HSS) Bits

High speed steel (HSS) bits are the most common type of drill bit on the market, and they’re suitable for all kinds of materials, such as wood, plastics, and metals. HSS bits are relatively inexpensive and very durable – although they will wear down over time.

They come in a variety of shapes, including twist drill bit, brad point bits, spade bit, and countersinks. When used with a proper sharpening technique, these bits can provide a professional-looking finish when drilling into wood or metal.

📍Carbide-Tipped Specialty Bits

Carbide-tipped specialty bits are designed for use with specific materials like masonry or tile. These high-quality tools feature harder tips that allow users to achieve precise results in tough materials like stone or ceramic tile without wearing them out quickly.

Although these bits usually come with a higher price tag than HSS ones, they often have their own integrated sharpening systems, which can help prolong their life even further.

📍Diamond Core Bits

Diamond core bits are designed specifically for drilling through hard surfaces such as concrete or bricks. These high-grade tools feature special diamond tips that make them ideal for creating neatly finished holes in brick walls or concrete floors.

However, they should not be used on softer materials like wood as they may cause damage due to the extreme hardness of the bit itself.

📍Carbon Steel Drill Bit

For tasks that will generate minimal amounts of heat, carbon tool steels are the material of choice. Drill bits can be made from either low or high-carbon steel, and each has its own specific use. Poorly tempered soft low carbon steel can’t cut through hard metals, but it makes short work of softwood and plastic.

To get the most out of them, you need to keep them sharp. When compared to other, more exotic drill bit materials, low carbon steel’s low price is the main benefit.

When compared to low-carbon steels, high-carbon steels have superior tempers, meaning they stay sharper for longer and don’t need as much upkeep. They are versatile, as they may be used to cut metal as well as wood, and are often preferred to low-carbon steels for use with the hardest of woods.

📍Cobalt Drill Bits

Cobalt drill bits are an incredibly versatile and efficient tool for drilling through a variety of materials. With the special alloy composition, they work faster and are more resistant to wear than other traditional drill bits. The cobalt construction provides strong cutting edges that make it easy to drill quickly and efficiently.

In addition, the durability of cobalt drill bits helps them last longer than other drill bits and makes them a great choice for high-volume or repetitive drilling jobs.

Considerations When Sharpening a Drill Bit

The drill bit is one of the essential tools in any handyman or home DIY enthusiast’s arsenal. From basic household tasks to larger projects, having a well-maintained and sharpened drill bit can be the difference between completing the job efficiently or spending hours struggling with sloppy results.

Here are some important considerations to keep in mind when it comes to sharpening a drill bit:

🧰Safety

The most important thing when sharpening a drill bit is safety. Always wear protective glasses when filing and use an appropriate clamp-hold system to secure your workpiece securely on your workbench. Take special care not to injure yourself with the file, especially near sensitive areas like fingers and eyes.

🧰Filing Angle

Different materials require different drill bit angles for optimal performance. For example, drilling into materials like hardwood requires more of an angle than softer metals such as aluminum or steel. Keep this in mind when filing, and adjust your angles accordingly.

🧰Tools Used

When sharpening a drill bit, you will need some specific tools at your disposal. A quality file set that includes both round and flat files is essential for creating smooth edges on your drill bit’s cutting blades while maintaining its original shape.

Additionally, you may want to invest in some diamond or carbide stones if you are planning on sharpening carbide-tipped bits, as these materials require their own specialized tooling for proper sharpening.

Use light pressure during filing but be sure to take enough passes. Therefore, all sides of each blade are even and there are no burrs left over from the filing process.

Finally, use a finishing stone to polish off any rough edges after the filing has been completed before using your newly sharpened drill bit again for further cutting jobs.

🧰Maintenance And Storage

It’s always important to properly maintain your tools so they can provide you with reliable service and a long life span. This holds true for the humble yet indispensable drill bit too!

After each use, make sure to clean away all residue from both flutes with a stiff brush. Then, store them away in an organized fashion inside their own dedicated storage box so they can remain free from contamination and rusting agents.

Furthermore, it’s also advised that oil be lightly applied onto the surface between uses in order to keep them functioning optimally for as long as possible!

Steps to Sharpen a Drill Bit at Home

Any handy person worth their salt should have a few basic tips and tricks for sharpening drill bits at home. Here are the steps needed to sharpen a dull bit:

Step ①: Prepare Your Materials

To get started on sharpening your drill bit, gather the materials that you need. You will need a sharpening stone or diamond file, some oil (olive oil will do just fine), and of course, the drill bit itself.

Step ②: Apply Oil To The Bit

Once you have all of the necessary materials, apply some oil onto the surface of the drill bit. This will help lubricate it and prevent any damage while you are sharpening it. Make sure to cover the entire surface with enough oil so that it does not dry up during the process.

Step ③: Secure the drill bit in a vise or clamp

It’s important that you have a secure grip on the drill bit while you are sharpening it. Clamp the drill bit in a vise or use a clamp to hold it in place. Make sure the bit is secure and will not move while you are sharpening it.

Step ④: Begin Sharpening

Now that everything is prepared, you can begin sharpening your drill bit. Using the grinding stone or file, move the tool from side to side with light pressure over the entire length of the cutting edge on both sides of the bit’s shank. Press too hard, and you risk damaging or ruining your drill bit. Press too lightly, and no effect will be made on its dullness!

Step ⑤: Test The Bit

Once you have finished sharpening your bit, test it by drilling into a piece of scrap wood or metal scrap that is similar in hardness to what you plan on drilling into eventually. If it performs well, then your job is done! Otherwise, repeat steps two through four until you are satisfied with the results.

How to Sharpen Drill Bits Using a Drill Bit Sharpener

When it comes to sharpening drill bits, investing in a drill sharpener can be the best way to get them back into shape. Not only does this save time, but it also ensures that your drill bits stay sharp and are ready for use whenever you need them.

Here’s how you can use a drill sharpener to sharpen up your drills.

Step ①: Ensure the Chisel is Secure and Cleaned

Before using the drill sharpener, the first step is to ensure that the chisel edge is secure in its clamp and completely cleaned of debris. This will allow the cutting blades of the drill sharpener to make contact with the material without any hindrance.

Step ②: Set The Sharpening Stone and Bit Guide Properly

You then need to set both the guide bar and its accompanying sharpening stone onto the machine arm in close proximity to one another. So, they align properly with the drill bit being clamped on the table. Doing this will ensure that when you sharpen your bit. It will remain centered and won’t wander from side to side as it cuts through each angle of your chuck.

Step ③: Adjust Speed Depending On Bit Quality

After ensuring all components are in place, adjust your speed settings depending on what quality of cut you want from your drill bit. Slower speeds are needed for higher precision cuts. Otherwise, faster speeds for more general-purpose uses, such as making holes in wood or metal paneling.

Step ④: Align Bit With Drill Sharpener and Begin Sharpen Process

Finally, align your bit with the spinning cutting blade of the drill sharpener before beginning by pressing down lightly on top of the chisel or sandstone grinding wheel.

Start slowly at first, increasing pressure after finding an appropriate grind angle. Don’t forget to take breaks in between rounds of drilling or grinding!

Once finished, check if all angles have been adequately sharpened by rolling them against a suitable surface such as an index card or similar material. If any bits aren’t correctly honed, they can be re-sharpened again until desired results are achieved.

Is It Possible To Sharpen A Drill Bit?

The answer is both yes and no. Depending on what type of material your drill bit is made out of and how much effort you’re willing to put into attempting to sharpen it. For example, standard high carbon steel (HCS) bits can often be manually sharpened using either a file or bench grinder. On the other hand, HSS bits require special tools such as diamond-coated files or grinding wheels in order to achieve any degree of success.

With that said, however, there’s still no guarantee that your attempt at sharpening will yield any tangible results — so always proceed with caution!

Frequently Asked Questions

Q: Can an angle grinder be used to sharpen small drill bits?

Sharpening tiny drill bits with an angle grinder can be difficult. It is important to keep the drill bit at the correct angle and to evenly distribute the force when using an angle grinder. Maintaining the drill bit’s structural integrity during sharpening also requires constant force.

Q: What can I do to extend the life of my worn drills?

Replacing worn out or broken pieces, brushing off dust and debris, drilling into material that does not require excessive force, and storing the drill in a dry place are all good ways to extend a drill’s life. Oil it periodically for added longevity.

Q: What exactly do auger bits mean?

Auger bits are special types of drill bits used for making holes in wood. They have a screw-like design which makes them efficient at boring through wood. Plus, their pointed tip helps prevent them from wandering while drilling.

Q: When should I replace the drill bit that I’m using?

Replace your drill bit if you notice that it has gone dull or is too old. You will know when it needs replacing due to its condition or age.

Q: Which direction should I drill in?

Drill in a clockwise direction whenever possible. This provides extra stability when drilling through tough materials. Always refer to your instructions before drilling with any tool.

Final Words

In conclusion, while it may be possible to sharpen some types of drill bits depending on their material composition and your skillset. Others simply may not benefit from being sharpened and should just be thrown away or replaced entirely. If you are looking for ways to save money and reduce waste, then considering sharpening might be worth exploring. Otherwise, purchasing new may end up being more cost-effective in terms of time/effort for some jobs!