Do you want to know which drill bits are for metal? Have you ever been confused about which drill bit to use for metal? If so, you’re not alone. It’s a common question with a lot of different answers.

Drill bits are available in various shapes, sizes, and materials, so much so that many hardware stores designate an entire aisle. While most drill bits can pierce many materials, not all of them can pierce metal without overheating and breaking. Therefore, you can easily locate metal-specific drill bits because they are labeled with this information.

This article will discuss which drill bits are best for metal, the different types of metal-specific drill bits, and how to use them.

What Are Drill Bits?

Drill bits are tool accessories used to create holes in various materials, such as wood, metal, and plastic. They consist of a head, or shank, that connects to the drill and a cutting edge that does the actual drilling work.

Drill bits come in a wide range of sizes and shapes, and the type of bit you will need will depend on the material you are drilling into and the size of the hole you need to create.

For example, a spade drill bit is designed for drilling through softwood, while a masonry drill bit is better suited for drilling through brick or concrete. Drill bits also have different finishes, such as coated or uncoated, which can impact their durability and performance.

Why Use Metal-Specific Drill Bits?

As we mentioned, not all drill bits can pierce metal without breaking. This is because metal is a much harder material than wood or plastic, and regular drill bits are not designed to withstand the heat generated when drilling through metal.

If a regular drill bit is used on metal, it will quickly become hot and smoke. The speed at which this happens will depend on the type of metal and the thickness of the metal sheet. In most cases, the drill bit will become so hot that it will break.

On the other hand, metal-specific drill bits are designed to withstand the heat generated when drilling through metal. They are typically made of high-speed steel or carbide, both very hard materials. Metal-specific drill bits also have a more aggressive cutting edge than regular drill bits, which helps to penetrate the metal surface quickly.

Which drill bits are for metal: The Material For Metal Drill Bits

There are three main metal drill bit materials: high-speed steel (HSS drill bit), carbide, and cobalt.

✅High Speed Steel

High-speed steel drill bits are made of a molybdenum and tungsten alloy, giving them their red hue. The drill bits are extremely hard, making them ideal for drilling through ferrous and non-ferrous metals. They can also withstand high temperatures without losing their hardness, making them ideal for use in power drills.

High-speed steel drill bits are also less likely to break than traditional drill bits. This makes them ideal for use in construction and industrial applications. When choosing a high-speed steel drill bit, selecting the correct size and type for the job at hand is important. Drill bits are available in various sizes, from small fractions of an inch up to several inches in diameter.

They are also available in different types, such as those with a 118-degree or 135-degree point. The type of drill bit you need will depend on the material you are drilling and the hole size you need to create. For most home projects, a standard 118-degree point will suffice. However, for tougher projects, such as drilling through concrete or brick, a 135-degree point may be necessary.

High-speed steel drill bits are an essential tool for any do-it-yourselfer or contractor. With their superior hardness and durability, they can make light work of even the toughest drilling jobs.

✅Carbide

Carbide (Carb) is the most brittle and toughest of the drill bit materials. It is usually used for production drilling, which requires a high-quality tool holder and equipment.

It is not suitable for use in hand drills or drill presses. These drill bits are made for the most difficult and demanding materials. They are used to drill through cast iron, non-ferrous metals, hardened steel, copper, brass, aluminum, fiberglass, and plastics.

You can also use them to drill through high-pressure and high-temperature applications. Carbide drill bits are available in various sizes, from small fractions of an inch to several inches in diameter.

✅Cobalt Bits

Cobalt bits are made of high-speed steel that contains 5 to 8 percent cobalt. This cobalt drill bit makes the steel harder than high-speed steel and gives the drill bit the ability to maintain a sharp cutting edge even at high temperatures.

In addition, cobalt drill bits are less likely to break than standard high-speed steel bits. However, they are more brittle and must be used with care to avoid breakage. Cobalt drill bits are best suited for drilling in stainless steel and cast iron. You can also use them on tougher metals such as titanium, which requires special care to avoid breakage.

Overall, cobalt drill bits are versatile tools that you can use on a variety of materials. With proper care, they will provide long-lasting performance and quickly work on any drilling project.

Types Of Drill Bits

There are many different types of drill bits available on the market. Each type is designed for a specific purpose. The most common types of drill bits are:

📍Step drill bit

Step Drills are mostly used for drilling holes in sheet metal, and their appearance is similar to the falling shape of a ladder step drill. Only those who need to work with metal sheets regularly will buy them. Step Drills allow you to drill boreholes of various diameters, deburr holes and conveniently clean away waste material.

📍Twist drill bit

The most common type of drill bit, the Twist Drill, is used for general-purpose drilling in many materials. It has a cylindrical shaft with sharp cutting edges and flutes that spiral up the shaft to remove waste material as the bit drills through the workpiece. The point of a twist drill is ground at a 60-degree angle, referred to as its drill angle. The most common sizes of twist drills range from 1/64″ to 1/2″.

📍Masonry bit

Masonry bits are used for drilling into stone, brick, and concrete. They have a carbide tip that is ground to a chisel point and flutes that spiral up the shaft to remove waste material. The tip of a masonry bit is not as sharp as that of a twist drill and will not cut through metal. Masonry bits are available in a variety of sizes, from small fractions of an inch up to several inches in diameter.

📍Flat Drill Bit

Flat drill bits are used for drilling in wood and other soft materials. They have a wide, flat, cutting edge that is ground to a sharp point. The cutting edge is set at an angle of 90 degrees to the shaft. This type of bit is also known as a dowel or spokeshave.

📍Straight Fluted Drills

Straight fluted drill bits are one of the most commonly used drill bits. Their popularity is due to their versatility and relatively low cost.

You can use straight fluted drill bits on various materials, including wood, metal, and plastic. They are also available in a wide range of sizes, making them suitable for small and large projects.

However, straight-fluted drill bits do have some drawbacks. They are not as effective at drilling through hard materials as other drill bits and are more likely to become clogged with debris. For these reasons, straight fluted drill bits are best suited for general-purpose drilling applications.

📍Double Fluted Drills

A double-fluted drill bit is a type of cutting tool used to create holes in various materials. The bit consists of two spiral flutes that are connected at the center. The flutes cut into the material as the bit is rotated, and the debris is ejected through the center of the bit.

Double fluted drill bits are used in various applications, including woodworking, metalworking, and plastics. They are available in various sizes and can be used with hand-held or power drills. Double-fluted drill bits are also known as two-flute drill bits.

📍Countersinking Drills

Countersinking drill bits create a conical recess in a workpiece, typically to receive a counterbored screw or plug. These bits are typically used on metal, wood, or plastic. The most common countersink type is the 60-degree angle, which is compatible with most screws and plugs.

However, other angles, such as 82 degrees, are also available. Countersinking drill bits are typically operated at high speeds and require coolant to prevent overheating. When used properly, these bits can produce clean, accurate results. However, improper use can damage the workpiece or cause the bit to break.

📍Hammer Bits

Hammer bits are used for drilling into masonry and concrete. They have a carbide tip that is ground to a chisel point and flutes that spiral up the shaft to remove waste material. The tip of a hammer bit is not as sharp as that of a twist drill and will not cut through metal.

Using Metal Drill Bits

Now that we’ve gone over the different types of metal drill bits let’s talk about how to use them.

Step 1: Select the Correct Drill Bit

As we mentioned before, selecting the correct size and type of drill bit is important for the job at hand. Drill bits are available in various sizes, from small fractions of an inch up to several inches in diameter. They are also available in different types, such as those with a 118-degree or 135-degree point.

The type of drill bit you need will depend on the material you are drilling and the hole size you need to create.

For most home projects, a standard 118-degree point will suffice. However, for tougher projects, such as drilling through concrete or brick, a 135-degree point may be necessary.

Step 2: Attach the Drill Bit to the Drill

Once you have selected the correct drill bit, it’s time to attach it to the drill. First, make sure the drill is unplugged. Next, locate the chuck, the drill part that holds the drill bit in place. Open the chuck by turning it counterclockwise. Insert the drill bit into the chuck and tighten the chuck by turning it clockwise.

Step 3: Set the Drill to the Correct Speed

It is important to set the drill to the correct speed before it begins. The speed setting will depend on the material you are drilling and the size of the hole you need to create.

For example, if you are drilling through metal, you will need to use a higher speed than if you were drilling through wood. Likewise, if you are drilling a small hole, you will need to use a lower speed than drilling a large hole.

To set the drill to the correct speed, locate the speed control knob and turn it to the desired setting.

Step 4: Begin Drilling

Once the drill is set to the correct speed, you can begin drilling. For most projects, it is best to start with a slow speed and increase the speed as needed. This will help to prevent the drill bit from overheating and breaking.

To begin drilling, hold the drill firmly in one hand and place the tip of the drill bit on the surface you wish to drill. Apply gentle pressure as you begin to drill. As the hole forms, increase the speed and pressure as needed.

When you have reached the desired depth, slowly release the pressure and allow the drill to come to a stop. Then, turn off the drill and remove the drill bit.

Tips for Using Metal Drill Bits

Now that you know how to use metal drill bits, here are a few tips to help you get the best results:

✅Identify the metal being drilled

Metals come in different types, such as cast iron, stainless steel, aluminum, brass, and bronze. Each type of metal requires a different type of drill bit. For example, cast iron is best drilled with a cobalt drill bit, while stainless steel is best drilled with a carbide-tipped drill bit.

If you are unsure which type of drill bit to use, consult a professional or the product manufacturer.

✅Use cutting oil

When drilling through metal, it is important to use cutting oil. This will help to lubricate the drill bit and prevent it from overheating.

Cutting oil can be purchased at most hardware stores. Simply apply a small amount to the drill bit before beginning to drill.

✅Drill slowly

When drilling through metal, it is best to drill slowly. This will help to prevent the drill bit from overheating and breaking.

If you find that the drill bit is getting hot, stop drilling and allow the bit to cool for a few minutes before continuing.

✅Use the correct drill speed

As mentioned earlier, the speed at which you drill will depend on the type of metal you are drilling and the size of the hole you need to create.

It is best to start with a slow speed and increase the speed as needed for most projects. Be sure to check the manufacturer’s instructions for more specific information on drill speed.

✅Use a center punch

When drilling through metal, it is important to use a center punch. This will help to create a starting point for the drill bit and prevent the drill bit from slipping.

To use a center punch, simply place the point of the punch on the surface you wish to drill and strike it with a hammer. This will create a small dent in the surface. Then, place the drill bit tip in the dent and begin drilling.

✅Wear safety goggles

When using any type of power tool, it is important to wear safety goggles. This will help to protect your eyes from flying debris. Be sure to purchase a pair of safety goggles that fit snugly and will not slip off during use.

✅Use gloves

Every now and then, you may need to stop drilling to remove a piece of metal shavings lodged in the drill bit. When doing this, it is important to use gloves. This will help to protect your hands from the sharp edges of the metal.

✅Take your time

Finally, it is important to take your time when drilling through metal. This is not a project that you should rush.

If you are having difficulty, stop and consult a professional. They will be able to help you troubleshoot the problem and get the job done right.

Frequently Asked Questions

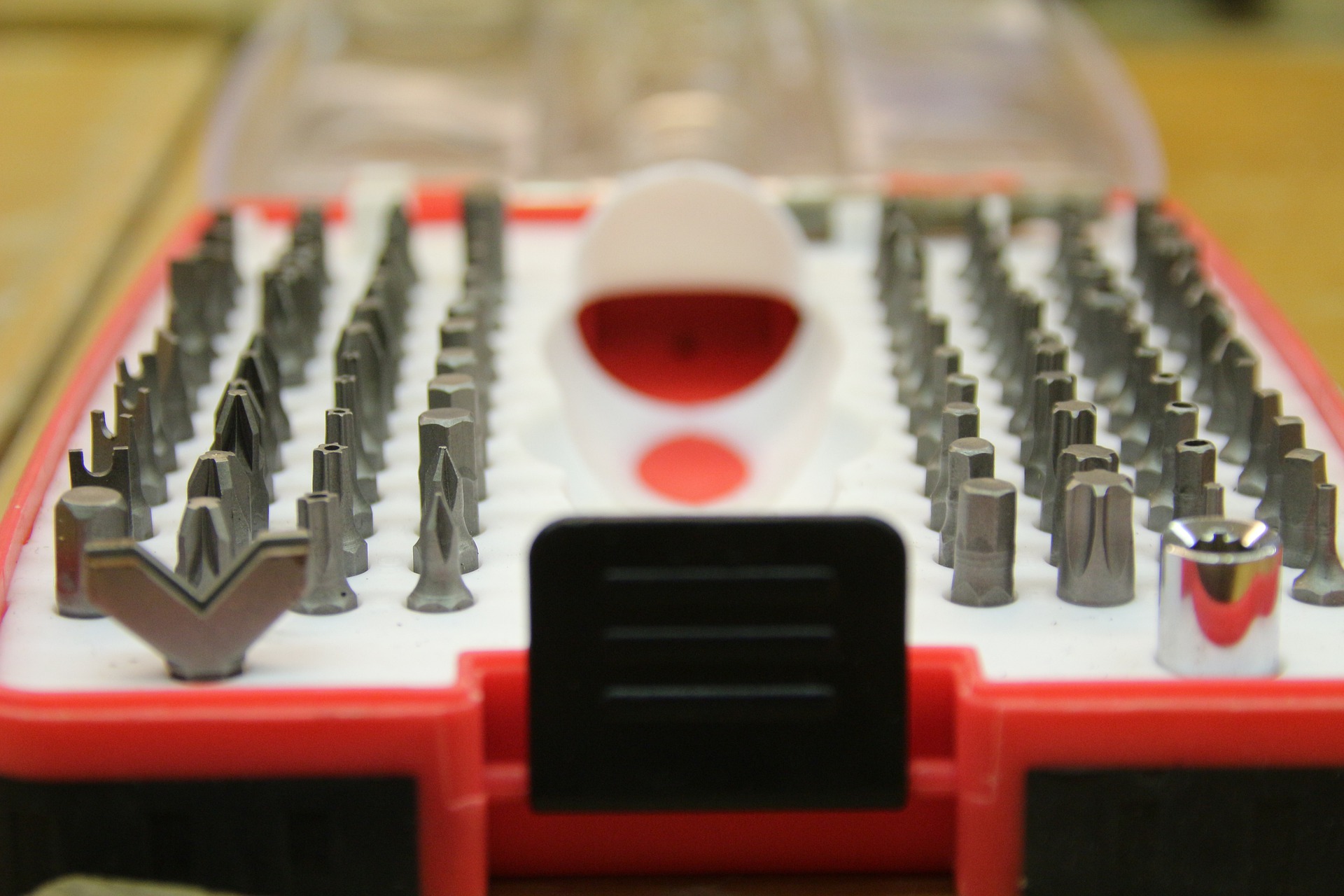

Q: Can I buy a drill bit set that includes all the different types of drill bits I will need?

A: Yes, many different drill bit sets are available. These sets usually come with a variety of drill bits that you can use for different projects.

Q: What wood drill bits should I use for a project?

A: The type of wood drill bit you should use will depend on the type of wood you are using. For example, if you are drilling through hardwood, you will need to use a different type of drill bit than if you were drilling through softwood.

Q: Where can I use titanium drill bits?

A: Titanium drill bits can be used on various materials, such as wood, metal, and plastic.

Q: Can I use a regular drill bit to drill through metal?

A: No, you should not use a regular drill bit to drill through metal. This could damage the drill bit and the metal surface.

Q: How do I know which drill bit to use for my project?

A: The best way to determine which drill bit to use is to consult the manufacturer of your product. They will be able to provide you with specific information on which type of drill bit to use.

Final Words

Drilling through metal can be a challenging task. However, by following the tips outlined in this article, you can complete your project. Remember to take your time, use the correct drill bit, and always wear safety goggles when using any type of power tool.

With a little patience and practice, you will be an expert at drilling through metal in no time!