To house electrical connections, a metal or plastic junction box is typically utilized. When a conduit run ends at a branch circuit, it is considered to be at the end of that run. Simply removing the cover of a junction box provides quick and easy access to the conduit inside, simplifying any necessary maintenance or upgrades.

What’s An Electrical Box?

To define an electrical box, let us categorize this electric product into three types. These are boxes that see heavy use in households:

- Round, 4-inch enclosures for use with various electrical devices such as lamps, sconces, smoke detectors, and CO detectors.

- Simple light switches and wall outlets can share a single-gang box.

- In a double-gang box, you can install two separate switches or a pair of duplex outlets.

- It’s important to keep in mind that electrical boxes serve as more than just storage spaces for wires and cables. They help prevent accidents like the disconnection of circuits, fires, and power outages.

▣ Electrical Box Sizes and Shapes

A variety of sizes and shapes of electrical boxes are available, each serving a specific function. There is a vast range of electrical box sizes available to meet a diverse variety of needs. The most frequent shape for electrical boxes is a conventional square. The metal or plastic box that has one on/off switch or one electrical outlet.

▣ Electrical Box Materials

The following items are typically used to construct electrical boxes:

- Made of steel with either a painted or galvanized coating,

- Iron foundry

- Aluminum

- PVC, or

- The transparent polycarbonate

▣ Electrical Box Installation Tips and Tricks

The initial step in electrical rough-in is usually installing outlets and switches in their respective boxes. Most people view installing electrical boxes as simple labor, on par with carpentry rather than electrical wiring.

Still, many people make the same mistakes while attempting a DIY project. The following simple guidelines can help you install an electrical box in a way that is both attractive and compliant with local building codes.

1-Stump-mount electrical box if needed

When installing electrical boxes, it is common practice to attach them to the face of a stud. Mounting a box directly to the wall studs, either by nailing it there or using an adjustable bracket, ensures that the box will remain securely in place for quite some time.

2-Placing wall boxes at a standardized height

The exact height at which wall switches and outlet boxes must be installed is not specified by the regulation. However, experts adhere to certain guidelines to maintain a consistent appearance. Try to keep all the electrical boxes to the same standard, whichever one you pick. Boxes with wildly varying heights are a telltale sign that the electrician who worked on them was not a pro.

3-Reference strip for drywall

Attaching a drywall furring strip to the exposed studs of a new construction project will provide a guide for nailing the wall boxes to the studs. When installing electrical boxes, it might be tricky to verify that the front corners are flat with the final drywall surface without a guide.

4-Make use of the box’s indicator tab

Nail-in electrical boxes made of plastic could contain measurement tabs every 3/8 inch. Using them, you may determine how far away from the studs’ faces the electrical box needs to be installed.

5-Nail box carefully

Electrical junction boxes are often made of plastic, which can cause them to break easily. Be gentle and precise with your hammer strikes as you nail the box together. Keep your fingers squarely on the stud. A heavy blow can cause the box to be pushed rearward along the stud’s face. Take particular precautions in the winter, as the box may shatter or break if struck when it is freezing outside.

6-To use it, alternate nail strikes

When hammering in nails, it’s better not to drive each one all the way in before moving on to the next one. But, rather consider moving back and forth between them, driving each one in approximately 1/4 inch at a time. By doing so, you can avoid warping or deflecting the box during the attachment process.

7-Take the pressure off your cords with some metal boxes

Lightweight cords for lighting, appliances, computers and phone chargers are often stored in just one or two of a home’s electrical boxes. Due to the low strain, these small cords put on outlets or electrical boxes, you can get away with using a plastic box in most situations.

Types of Electric Boxes

As a result of the huge selection of electrical boxes out there, it can be challenging to zero in on the one that is best suited to your specific requirements. See below for a rundown of the most popular numerous electrical boxes and some advice on how to pick the perfect one for your next job:

🗹 Weatherproof Boxes

For obvious reasons, outdoor use is intended for weatherproof boxes. With the included gasket, the cover is sealed tightly, preventing the infiltration of water and vermin. The measurements in this scenario will start with the width, then the height, and finally the depth.

🗹 Ceiling Boxes

Chandelier receptacles, or “ceiling boxes,” have evolved into indispensable fixtures in modern construction. They are made to work with a wide range of light sources, from chandeliers and ceiling fans to pendants and track lighting. Conveniently, ceiling boxes help keep light fittings in place.

🗹 Wall Boxes

In order to prevent unauthorized access to circuit breakers, power outlets, and other potentially hazardous electrical components, wall boxes are commonly installed. High IP classified wall boxes are typically used with appropriate locks when it is vital to keep electrical equipment free from external conditions like moisture for safety and functionality.

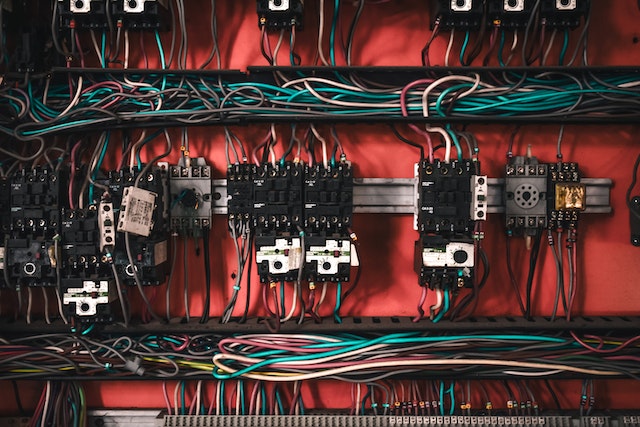

🗹 Junction Boxes

Electrical connections are protected in junction boxes. The electrical tape could be used to join multiple wires together. Ensure that the one you choose has the appropriate dimensions for the intersection where it will be placed. Multiple wires can be joined with their help.

What is a Junction Box?

To house electrical connections, metal or plastic junction box is typically utilized. When a conduit run ends at a branch circuit, it is considered to be at the end of that run. Simply removing the cover of a junction box provides quick and easy access to the conduit inside, simplifying any necessary maintenance or upgrades.

Wiring can be damaged by environmental factors like corrosion and extreme temperatures. So, junction boxes shield it from both. Last but not least, junction boxes shield electrical connections from accidental or purposeful interference.

Junction Box Wiring Basics

A junction box stores wire connections that distribute electricity from a central source to several different outputs. It’s not uncommon for several lights to be powered by a single electrical source housed in a junction box, which would only have one wire coming into it.

In general, the length of a junction box is between 2 1/2 and 3 1/2 inches, and it’s typically composed of metal and hard plastic. Identifying which material is better, a metal or plastic junction box ,depends on its intended use.

Light fixtures can be supported by metal junction boxes; plastic junction boxes will break under the weight. One more distinction is the ease with which plastic junction boxes can be installed as opposed to their metal counterparts. But a regular junction box is just meant to hide wire splices, and it can be made of metal or plastic.

Metal vs. Plastic Junction Boxes

Metal (often aluminum and stainless steel) or plastic can be used to create the electrical junction box. In order to properly connect to the junction box, you’ll need to use specialized wires that are compatible with its construction material.

When defining a junction enclosure for a commercial application, one of the crucial options is whether to use a metal or plastic box. Metal-sheathed cable (also referred to as armored BX cable) and metal conduit require a metal electrical box.

In addition, an electric aluminum box and a metal electrical box are typically required when working with metal-sheathed cable or metal conduit. For non-metallic electrical cables, plastic electrical casings are the norm.

🗹 Plastic Junction Boxes

Plastic junction boxes provide numerous benefits, including as affordability, portability, and installation simplicity. On the other hand, they aren’t always the greatest option. The common substitute for plastic when it doesn’t make sense is a metal box. Whether you need a plastic or metal box for indoors or outdoors, you may find a wide variety of shapes and sizes.

🞹 Advantages and Disadvantages of Plastic Electrical Boxes

PVC (polyvinyl chloride) electrical boxes, composed of plastic, are commonly used in domestic settings. They don’t take up much space in storage and don’t necessitate the time-consuming grounding process, making them an attractive option. However, PVC will melt at very high temperatures and does not conduct electricity. Electrical boxes made of plastic have the drawback of breaking under stress and melting when overheating.

🞹 When to Use Plastic Junction Boxes

You are strongly encouraged to make use of a plastic electrical box, however, doing so is not mandatory. There is no requirement in the electrical code that says you have to use NM cable inside the plastic boxes.

The most important thing is for the application to have some sort of solid foundation. Wires protected by a metal sheath can only function as a ground if they form a bond with the metal of the electrical box. Inadequate grounding precautions, such as using metal-clad wiring in plastic electrical boxes, can be extremely hazardous.

🞹Wire Splices in Junction Boxes

In order for a structure to be in compliance with electric codes, all wiring splices must be made inside of a junction box, yet this is commonly overlooked. Exposed wire splices pose a unique threat since they can be stepped over, cause sparks to fly, or even be mistaken for toys by curious youngsters or animals. Wire splices benefit from junction boxes because the spliced region may be easily identified.

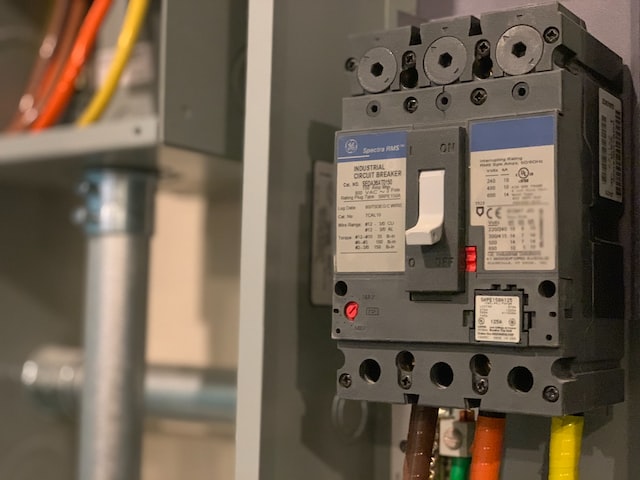

🗹 Metal Junction Boxes

Metal junction boxes are incredibly resilient and can survive a wide range of extreme temperatures, as well as open flames, crushing shocks, and icy low temperatures. Furthermore, they are excellent electrical grounding points for components that have metal sheathing or other electrical grounding needs.

🞹 Advantages of Metal Electrical Boxes

When it comes to protecting your electrical wiring, nothing beats the durability, safety, and longevity of metal electrical boxes. Because of their greater performance and longevity, metal boxes are often mandated by building codes.

A metal electrical box must be used when a metal-sheathed cable and metal conduit enter and exit the electrical box. In times when non-metallic cables enter and exit the box, you have the option to switch to a plastic enclosure.

🞹 The Time to Choose Metal Boxes

1-Prevention of electrical shock

The BX cable you’re using has a metal jacket. To prevent electrical shock, a metal-sheathed cable must be connected to a metal junction box.

2-When attaching to the stud

The electrical box must be fastened firmly to a stud. Metal electrical boxes are suitable for the extra-strong stud attachment you’ll require because of their rigidity and resistance to warping.

3-For wire protection

The area of your project is a public one. Non-recessed electrical boxes are those that are not flush with the surrounding wall or ceiling and are instead mounted to the surface directly, such as in an unfinished basement (usually a masonry wall). Given the increased exposure of wires in such uses, the recommended junction box for protective purposes is a metal box.

It is a requirement to use more robust electrical junction boxes. The plastic used in some electrical enclosures can break under sufficient force. In most cases, metal is the better material for electrical enclosures.

🞹 When Not to Choose a Metal Box

The non-metallic encased wire is what you’re employing here. While plastic junction boxes and Romex wire go hand in hand, metal enclosures are also a viable option. Use the metal-sheathed wire with plastic enclosures, but also follow the proper grounding procedures at all times.

Use plastic or metal boxes with equal confidence if you’re watching your pennies. When compared to metal electrical boxes, plastic ones are often more affordable and necessitate fewer supplementary materials, such as clamps, for installation. Keep in mind that if your application calls for metal enclosures, no amount of cost reduction is worth sacrificing safety.

Easily installed and relocated junction boxes are a must. In most cases, there is a mitigation of risk of damage from sharp edges on sheet metal enclosures by utilizing protective gear, such as gloves, or by opting for a finished enclosure.

Frequently Asked Question

Q: Will a plastic connection box be enough on its own?

If you’re working with non-metallic encased wire, it is more appropriate to use a plastic electrical box (often called Romex wire). Typically, the process is to install a Romex wiring in plastic junction boxes, but metal enclosures are also a viable option, depending on the project.

Q: To what extent is grounding of metal junction boxes required?

If metal is the component of your raceway and boxes and you don’t plan to splice or terminate any wires within the box, then you can skip the grounding pigtail. So, a grounding pigtail is optional in a genuine pull box. You should install a grounding conductor and a junction box or device box at the location in question.

Q: To what extent would I be able to mess through with a plastic electric box?

If only non-metallic cables enter and exit a home’s electrical box, a plastic is a good box component instead of metal. However, plastic electrical boxes can bend or shatter under pressure, and PVC can melt from excessive heat.

Q: Do plastic electrical boxes work with metal studs?

The following ways may help in the installation of a conventionally new-work box into an actual wall:

- Cut holes in the drywall next to a stud.

- Filling the void with the plastic box and pressing it on the stud, inserting a screw into the stud through the plastic.

Q: Do electrical boxes need to be metal?

It’s usually up to you whether to choose a plastic or metal electrical box, as it comes down to factors like cost, maintenance, and convenience. There are, however, a few instances where the option is glaringly obvious, most notably in regards to grounding. Electrical contractors use both plastic and metal junction boxes, although most DIYers prefer the plastic ones

Q: Why are junction boxes made of metal?

For certain occasions, metal containers are ideal. Metal electrical boxes have significantly outlasted their PVC counterparts due to their superior strength, fire resistance, and indestructibility. When used in electrical wiring, they provide the highest possible safety. Metal junction boxes are also extremely difficult to damage in any way.

Final Thoughts

When you need to house a lot of cables, the durability and space of metal containers are ideal. If you’re using a plastic container, you may want to consider replacing it with blank covers instead. In order to use the holes, simply insert a suitable-sized connector. Wherever possible and light in weight, I opt for plastic. When the job calls for anything medium to hefty, I reach for metal.