Attention all other do-it-yourselfers! We’re here today to discuss a familiar cause of frustration for those of us who enjoy woodworking: a drill not going through wood. Having your drill bit abruptly stops when it meets wood is one of the most unpleasant things that can happen while working on a project. But have no worry; in this post, we’ll investigate why your drill could not be penetrating the wood, as well as some solutions. Okay, everyone strap in, because we’re about to get deep into the world of fixing drills that aren’t working. So grab your safety gear and let’s start drilling!

Possible Reasons For Drill Not Going Through Wood

While a drill can be an incredibly versatile and useful tool in woodworking, there are several reasons why it may fail to penetrate the wood. Understanding these common reasons can help you troubleshoot the issue and get back to work on your project. So here are the common causes for dill not going through the wood:

🟦 Dull Drill Bit

A drill bit’s effectiveness and penetrating power can be drastically diminished when it becomes dull. The fact is that a dull drill bit is a common cause of drill failure.

Since wood fibers are so tough and sturdy, a drill bit that can easily slice through them must be extremely sharp. On the other hand, a dull bit won’t be able to efficiently cut through the material, and it will only spin in place, getting you nowhere near your goal of drilling a hole.

A worn-out drill bit is not only useless but also potentially harmful. The operator risks injury or project damage if the drill binds, kicks back, or breaks due to a dull bit.

🟦 Incorrect Drill Bit

One possible reason is that you’re using the wrong type of drill bit. Each drill bit is designed for a specific purpose, and using the wrong one can lead to disastrous results. In this case, it seems like you’ve grabbed a wood drill bit, which is meant to drill through wood, not metal. Using a wood drill bit to drill into metal is like trying to cut through a steak with a butter knife – it’s just not going to work.

So why is it so important to use the correct drill bit for the job? First of all, using the wrong bit can damage your drill and make it less effective in the future. But more importantly, it can compromise the quality and safety of your work. If you’re building something that needs to withstand weight or pressure, using the wrong drill bit can weaken the structure and make it more prone to breaking or collapsing. And if you’re working with metal, using the wrong bit can cause the material to overheat, potentially leading to warping, cracking, or other damage.

🟦 Wrong Drill Speed

The drill speed refers to the number of revolutions per minute (RPM) that the drill bit makes while drilling. This factor is critical because it affects the ability to penetrate the wood surface without causing damage to the drill bit or burning the wood. It’s therefore essential to adjust the drill speed to ensure that you get the best results.

If the drill speed is too low, the drill bit won’t be able to penetrate the wood, no matter how much pressure you apply. This can cause frustration and waste time, especially if you have to drill multiple holes. On the other hand, if the drill speed is too high, it can cause the wood to burn and damage the drill bit. Burning wood can leave unsightly marks on the surface, which may require sanding or repainting, and replacing a damaged drill bit can be costly.

🟦 Lack of Pressure

As any experienced woodworker knows, drilling is a critical step in the creation of any wooden masterpiece. But did you know that the amount of pressure you apply during drilling can make or break your project? Applying the right amount of pressure is crucial to achieving a clean and precise borehole.

Without sufficient pressure, the drill bit will struggle to penetrate the surface of the wood. This can lead to frustratingly slow progress, a dull bit, or even worse, a botched hole that’s jagged or uneven. On the other hand, if you apply too much pressure, the bit can quickly become overheated, lose its sharpness, and even cause the wood to split. This is the last thing any woodworker wants, especially after all the time and effort put into selecting the perfect piece of wood.

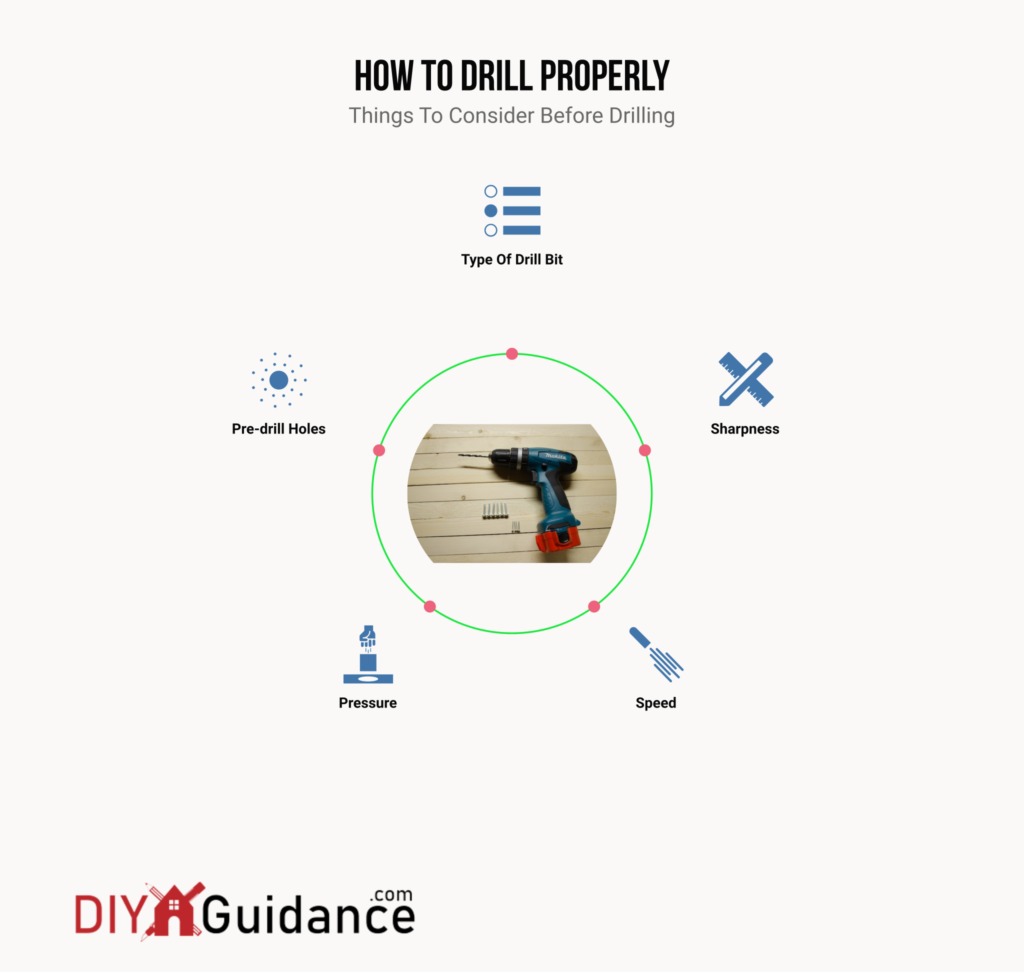

Tips For Drilling Through Wood Successfully

If you’re having trouble drilling through wood, you may improve your technique and attain the desired results by following a few simple guidelines. So, if you want to know how to make your drill bore holes in wood properly, read the tips listed below and have clean and straight holes:

🟩 Use the right type of drill bit

Make sure you have a wood drill bit on hand if you need to drill into wood.

These wood-specific drill bits are designed to speed up the drilling process. Their one-of-a-kind form and slant make them perfect for slicing cleanly through wood fibers without causing cracking or splitting. Wood drill bits are suited for usage with softer woods, as opposed to metal drill bits, which are meant for harder materials.

With the help of a wood drill bit, you may easily bore holes of uniform size and shape into your woodworking creations. There is less of a chance that you’ll ruin your drill or the wood, both of which would be expensive and annoying to replace.

🟩 Use sharp drill bits

A rough hole may be the result of using a dull drill bit, and it may not even penetrate the wood completely. Instead, it’ll just spin there, doing unnecessary wear and tear on the wood and the bit itself through heat and friction.

However, things change when a sharp drill bit is used. The wood is easily cut through by the bit, and the resulting hole is flawless and precisely the right size and form. You won’t have to sweat, squirm, or clean up any messes; instead, you’ll have a clean, well-formed hole in which to move on to the next process.

Therefore, make sure your drill bits are always in good condition. Before beginning, make sure all of your tools are in good working order and replace any that are damaged or worn. The quality of your woodworking projects will increase, and you’ll experience a surge of self-assurance and a sense of fulfillment as a result.

🟩 Adjust the drill speed

The drill bit can become damaged by overheating if the speed is too high when working with thicker wood, so be sure to reduce it. Also, you’ll have more control over the drill at the lower speed, meaning the bit is less likely to wander and make a muddled hole. By slowing down the rotational speed, you may make a clean, precise cut, resulting in a flawlessly drilled hole every time.

However, a higher drill speed will offer you the control you need to make small, accurate holes in thinner wood. Rapidly increasing the drill’s RPM will help the bit slice through the wood without scorching or charring the surface. This rate is great for detailed woodworking projects that necessitate numerous little holes.

🟩 Apply adequate pressure

It’s vital to keep in mind that the drill bit needs to be pressed firmly into the board in order to make a hole. If you don’t use enough force, the drill bit can not penetrate the wood completely, leaving you with an imperfect and unusable hole. However, if you use excessive force, the wood may break, which would be the end of your effort.

The trick is to strike a balance between applying too little or too much force. It’s important to provide just enough force to maintain the bit working consistently through the wood without splitting it. Drilling clean, precise holes in any kind of wood may take some effort, but if you discover the appropriate pressure, you can do it with ease.

Applying equal force from both hands while maintaining a centered body position above the drill should help you get the desired amount of pressure. In order to prevent skewed or unequal holes, you should hold the drill bit perpendicular to the wood’s surface. Following these instructions will allow you to exert just the proper amount of force, resulting in perfectly drilled holes every time.

🟩 Pre-drill holes

A pilot hole drilled before actually drilling a hole allows for more precise and controlled drilling. This not only helps to keep the wood from splitting or splintering but also guarantees a straight and exact hole. Hardwood is notoriously dense and sturdy, therefore this is of paramount importance.

In addition to making it easier to drill through the wood, pre-drilling makes it possible to use less pressure and force. You can get more done in less time without worrying about breaking any of your equipment. You can make holes that are clean, precise, and ready for whatever hardware you need to attach with the correct drill bit and drilling method.

Types Of Drills For Woodworking

There are several types of drills available in the market. Let’s take a look at some of the most commonly used drills for woodworking.

🟪 Cordless Drill

Because they are cordless, drills allow you to work in any setting, be it your backyard, a construction site, or even the middle of nowhere.

As battery technology has improved, cordless drills have become competitive with their corded counterparts in terms of power and runtime. This allows you to take on the most challenging tasks without worrying about running out of juice or having to keep an extension cord handy.

Since cordless drills are lightweight and compact, they may be moved from one worksite to another without difficulty. You can discover the ideal drill for your purposes among the many sizes and designs offered.

🟪 Hammer Drill

A regular drill isn’t up to the task of drilling into concrete or masonry. The hammer drill’s percussion mechanism strikes the drill bit with such force that it can bore through even the toughest materials with relative ease.

You can compare a hammer drill to a tiny jackhammer in terms of its effectiveness. The mechanism’s fast, hammering movement helps break up the dense material, making drilling much simpler. This is especially helpful when drilling into brittle materials like brick or concrete.

When drilling into tough materials, a hammer drill can be a huge time- and labor-saver. It can be time-consuming and physically exhausting to manually chip away at the surface before drilling without a hammer drill. No sweat, no trouble: a hammer drill makes short work of any task.

🟪 Drill Press

A drill press is an indispensable piece of equipment if you want to take your drilling to the next level. A drill press, unlike a hand drill, is a stationary machine that may be bolted to a workbench or stand, allowing for greater precision and accuracy when drilling.

The ability of a drill press to consistently drill at the same angle and depth is one of its primary benefits. Since the drill bit is fixed, you can count on consistently straight and uniform holes, and the tilting table gives you control over how deep you want those holes to be. This makes it perfect for carpentry, metalworking, and even jewelry-making jobs that call for precise dimensions and repeatable hole patterns.

🟪 Brad Point Drill

This woodworker’s ideal tool drills clean, precise holes in wood. Its precise point starts the hole accurately, so your drill bit won’t wander or slip.

The Brad Point drill bit’s fluted edges also remove wood chips as you drill. Without debris clogging the drill bit, you can drill deeper and more quickly. As a result? Always has a smooth, perfect hole.

Brad Point drill bits are effective and elegant. Its precision-engineered features and sleek, slim shape make it glide effortlessly through the wood.

🟪 Spade Bit

Spade bits are not merely paddle-shaped drill bits. It simplifies and accurately drills large wood holes. Every DIYer should have a spade bit for house repairs and more difficult projects.

You can get the right spade bit size for your project. You can select the suitable bit from 1/4 inch to 2 inches. They’re great for drilling holes for plumbing, electrical, door locks, hinges, and cable management.

Flatness distinguishes the spade bit. This gives a cleaner cut and smoother finish than other drill bits, which can leave rough edges or splinter wood. Spade bits make professional-looking holes easily.

Final Words

I hope this woodworking advice and skills helped you after reading this guide. You can drill clean, accurate holes in wood without damaging or frustrating it by following the right methods and using the right instruments.

Always use the suitable drill bit for your project and the optimum speed and pressure for the wood. Take your time and use a guide to keep the drill perpendicular to the wood. Wear protective gear to avoid flying debris and injuries.

Drilling into wood is crucial for all woodworkers. With skill and dedication, you can make precise, professional-looking holes in all your woodworking projects. Start drilling and enjoy a job well done!