Are you aware of the difference between a screwdriver vs impact driver? Do you have a project or a DIY repair requiring a screwdriver? Have you ever wondered which tool is right for the job—a regular screwdriver or an impact driver?

Having the right tools is essential when it comes to home improvement and DIY repair projects. But what happens when facing more than one choice for a particular job? Choosing between a screwdriver and an impact driver can be tricky if you don’t know the difference between them.

In this article, we’ll explore the differences between these two types of drivers. Therefore, you can decide which tool is best suited for your project.

How Does Screwdriver Work?

Screwdrivers are a tool used in many construction and home improvement projects. But have you ever wondered how they work?

In simple terms, the head of the screwdriver creates friction to turn screws. This same process is used in any application of manual screw driving. Whether it be to repair an appliance or build a birdhouse. All that’s needed is some leverage and a bit of strength directed in the right direction.

The secret behind the success of a screwdriver lies in its design which consists of two parts; namely, a handle and a transforming device within it that converts rotary motion into linear motion. These two parts make up the time-tested mechanism known as cam-action technology, allowing us to turn screws with much less effort than if done by hand.

However, many homes and businesses have abandoned the usage of traditional screwdrivers in favor of the more efficient and multipurpose power drill because of its ability to bore holes.

The 8 Different Types of Screwdrivers

Different projects require different types of screwdrivers. Knowing each type and its functions makes it easier to choose the best screwdriver for the job. Here’s a look at the eight different types of screwdrivers and when they should be used.

🪛 Phillips Head Screwdriver

The Phillips head screwdriver is one of the most common types of screwdriver. You can use it on a variety of materials, including wood, plastic, and metal. It consists of a four-sided tip that fits into a cross-shaped indentation found on screws.

🪛 Flat Head Screwdriver

A flathead screwdriver is designed for use with slotted screws. These screws have one straight line cut down the face, allowing them to be tightened or loosened with a flathead screwdriver. These types of screwdrivers come in various sizes depending on the size of the slot present in the screws.

🪛 Hex Key (Allen) Screwdriver

Hex keys (or Allen keys) are small L-shaped tools for inserting hexagonal bolts or screws into materials such as wood, metal, or plastic. They are frequently used in furniture assembly and other DIY projects because they don’t require as much torque as traditional screwdrivers do when being inserted into a surface.

🪛 Torx Screwdriver

Torx screwdrivers feature a star-shaped tip that is designed to fit into torx-head screws. It usually have six points instead of four like those found in Phillips head screws. This type of driver provides more torque than traditional drivers. You can also use this to remove stuck or rusted screws due to its high durability and grip strength.

🪛 Pozidriv Screwdriver

Pozidriv differs from Phillips head drivers by having an extra land at its center for increased contact between the driver and the fastener’s recesses, allowing for greater resistance against slippage during installation and removal processes compared to Phillips head drivers.

This makes Pozidriv ideal for applying more torque without damaging either component when dealing with stiffer fasteners, such as those made from stainless steel or brass, which require more force when installing/removing them from surfaces.

🪛 Robertson Screwdriver

The Robertson drive features a square-shaped tip with a tapered point that is designed to fit into Robertson square drive recesses found on various fasteners such as shelf pins, drawer slides, door hinges, etc. With their shallow drive angle, these types of screws provide higher levels of torsional strength than other drives like Phillips’s head.

It allows them to remain securely fastened even after long periods under stress or vibration. It’s the ideal choice whenever superior holding power is required over a smooth installation/removal process provided by standard drivers like Philips heads, etc.

🪛 Tri-Wing Screwdriver

Tri-wing (or Y shape) screws are commonly found on gaming consoles such as Xbox, PlayStation, etc. These triangle-shaped drives feature three wings located at 120° intervals around their perimeter – making them almost impossible to unscrew without specialized Tri-Wing drivers.

🪛 Spanner Screwdriver

Spanner screws employ two slots located 180° apart from each other, which run along its circumference. It allows these special drivers with two matching prongs inserted at opposite sides simultaneously to engage onto fastener heads, providing better security than most conventional designs.

🪛 JIS (Japanese Industrial Standard)

This type of screwdriver differs from its traditional counterparts since it has been designed to fit Japanese-style screws with a slightly different profile. To ensure compatibility, JIS screwdrivers have been designed to fit the specialized profiles perfectly and feature a tapered tip in an ‘X’ cross shape.

As such, they are perfect for tightening or loosening crosshead screws with precision and accuracy. Something that normal drivers just can’t replicate!

Manual Screwdriver and Electric Screwdriver

One of the most common tools used in many projects is screwdrivers, which come in two basic varieties: manual and electric. Below, we’ll look at some of the primary benefits and drawbacks for both to help you decide which is best suited for your next endeavor.

Manual Screwdriver Pros & Cons

One of the main advantages of manual screwdrivers is their portability and relative ease of use compared to an electric model. There’s no need to be near an electrical outlet or worry about tripping a circuit breaker if using several powered tools at once. A simple ratcheting system does the trick.

Plus, manual screwdrivers often cost far less than electric models, saving you money upfront and over time due to not needing replacements as often. That said, manual screwdrivers also have some drawbacks that must be considered when choosing between them and an electric model.

For one thing, they require more effort from the user when it comes to tightening or loosening screws and bolts. Especially if dealing with tougher materials such as dense woods or heavy-gauge metal like those found in automotive repairs. Secondly, they can be quite slow if multiple screws need fastening since there’s no power assist. This can result in considerable frustration if tight spaces or awkward angles are involved where speed might be essential.

Electric Screwdriver Pros & Cons

On the other hand, electric models are ideal for larger jobs involving multiple screws. Plus, those located in hard-to-reach places that would otherwise require tedious maneuvering around obstacles with a manual version. They provide much quicker results than manually driven style screwdrivers. Thanks to their motorized design that does most of the work for you, which could save hours depending on your project’s complexity.

Also worth noting is that electric versions usually come with variable settings. Therefore, you won’t strip out any screws should you forget what material you were working on. A mistake that’s all too easy with a manual ratcheting device! Of course, there are downsides to consider when it comes to powered tools like:

- Wiring costs (if running electricity)

- Weight concerns (as electric models tend to be bulkier than their handheld versions)

- Noise levels could potentially disturb neighbors or family members depending on your home or work environments during use.

Additionally, they generally cost more than manual versions, which may limit budget constraints, thereby narrowing down your choices significantly.

What is an Impact Driver?

An impact driver is a type of cordless drill driver with a 1/4″ hex bit holder that holds small screwdriver bits instead of a typical 13mm chuck.

They’re all about high torque combined with high impact. Typically, the torque output of an impact driver exceeds that of even the most powerful combi drill. These power tool drills use rotational force like any other, but in addition to that, they also have these benefits.

Usually, you can rapidly drive long, wide, and massive screws into the toughest materials thanks to the torque at your disposal. The head length is an important factor when shopping for a cordless impact driver.

If you need to use your impact driver in a confined area, the shorter the head length, the better. You can get by with just one speed on the cheaper ones. However, having 2 or more speeds allows for greater precision and control over speed and torque.

Types of Impact Drivers

There are three main types of impact drivers you should know about – compact, cordless, and corded. Understanding the different types of impact drivers on the market is key to finding the one that best suits your needs.

🧰 Compact Impact Drivers

Compact impact drivers are lightweight and easy to maneuver in tight spaces. Their small size makes them ideal for completing projects around the house, such as installing kitchen cabinets or constructing a garden shed. They’re battery-powered and provide higher torque than other power drills. This is a great choice for those who don’t want to be limited by their cordless drill’s range.

🧰 Cordless Impact Drivers

Cordless impact drivers are excellent for professionals who need to take their toolboxes with them on job sites. These impact drivers offer greater flexibility than traditional corded models because they can go anywhere there is a power outlet due to their battery-powered motor. The downside is that they require frequent recharging of their batteries to keep working at high levels of efficiency.

🧰 Corded Impact Drivers

Corded impact drivers operate using electrical power from an outlet, making them perfect for more powerful jobs where more sustained torque is needed over long periods of time without interruption due to fading battery life. This makes them great options for contractors and larger DIY projects where a higher amount of force might be necessary than what cordless models could provide efficiently enough.

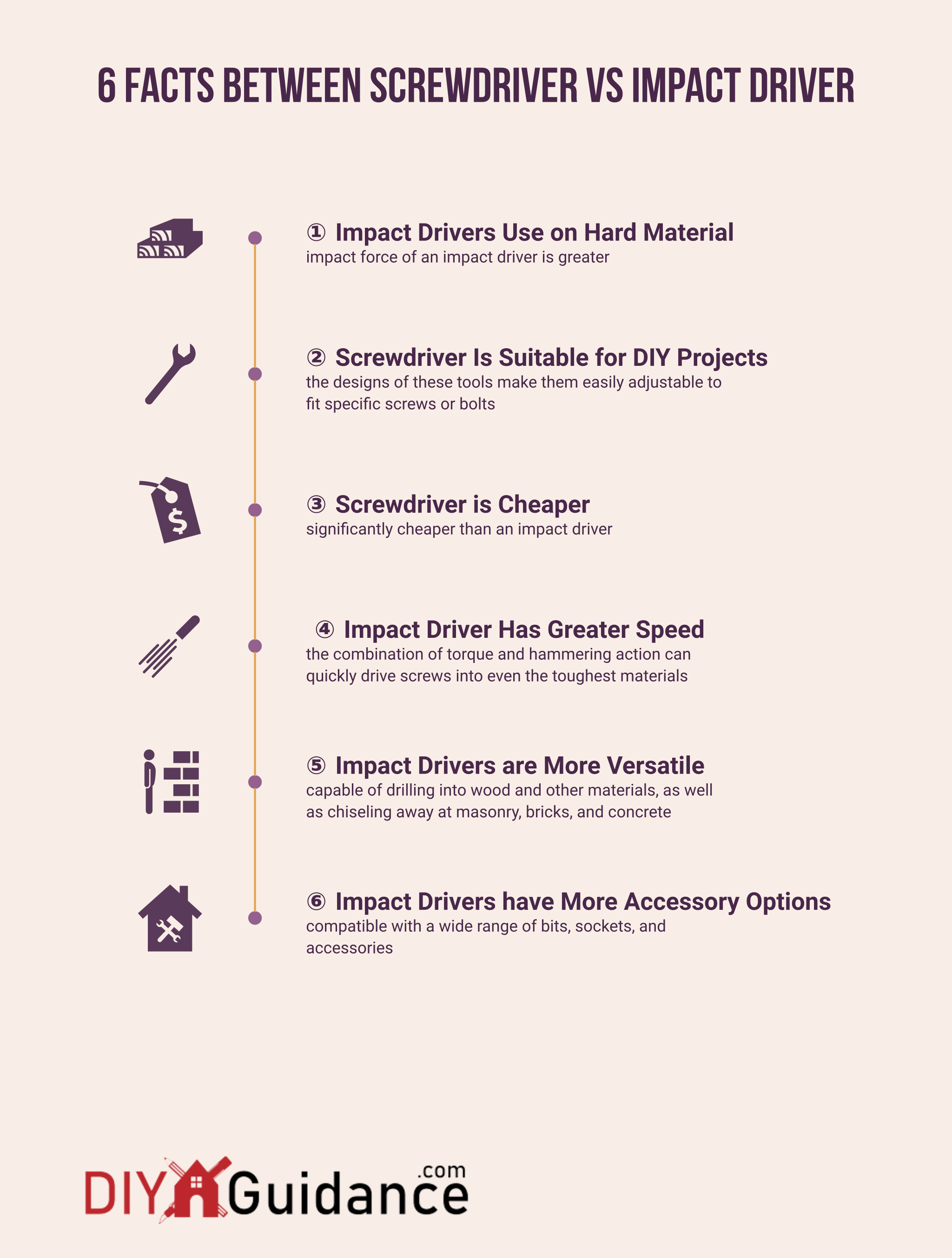

6 Facts Between Screwdriver vs Impact Driver

Are you trying to decide between a screwdriver and an impact driver? It can be difficult to determine the right tool for the job. To help you decide, let’s take a look at some of their key differences:

① Impact Drivers Use on Hard Material

Impact drills combine stronger torque with a forward and back action like hammer drills, boosting screw impulsion. For extended or continuous usage, impact drivers can screw deeply into hefty materials.

The impact force of an impact driver is greater. As a result, it can be used to drive screws into hard materials. However, electric screwdrivers are not used to drive screws into hard materials. These are typically used to tighten or remove screws from objects such as tools, toys, and so on.

② Screwdriver Is Suitable for DIY Projects

For DIY projects, the screwdriver is more suitable than the impact driver. The screwdriver comes in wide varieties, each providing its own benefits and features for a given task. Whether you are using a flathead, Phillip’s head, or Torx bit, the designs of these tools make them easily adjustable to fit specific screws or bolts.

Plus, they provide more range in controlling the torque, making them better suited for delicate jobs. What’s more, because you can quickly switch it out for another bit or size to fit different screws and bolts, you don’t have to buy an entirely new tool if your project calls for something specific.

③ Screwdriver is Cheaper

Should you select the traditional screwdriver or opt for the more advanced impact driver? Well, if cost is your priority, then you’ll be glad to know that the screwdriver is usually significantly cheaper than an impact driver. This makes it attractive to DIYers and amateurs on a budget looking for their next handy tool. Although not as powerful as its trendy counterpart, a good quality screwdriver will often do a better job driving and removing screws than you might expect. Even when faced with those thick woodscrews! So don’t write off the humble screwdriver just yet. It may be cheap, but it still packs enough punch to get the job done!

④ Impact Driver Has Greater Speed

If you’re after speed and power, then an impact driver is the way to go. The combination of torque and hammering action can quickly drive screws into even the toughest materials with minimal effort. This makes it great for larger projects where time is of the essence, such as furniture assembly or deck building, where you might be using many screws in a short period. Impact drivers also feature variable speed settings. It allows you to adjust the speed and power depending on what type of material you’re working on, giving you greater control over your project’s outcome.

⑤ Impact Drivers are More Versatile

Do you want a tool that can do more than just drive and remove screws? Are you thinking of taking on a new project that involves drilling and chiseling? Then an impact driver is a tool for you. Impact drivers are capable of drilling into wood and other materials, as well as chiseling away at masonry, bricks, and concrete.

⑥ Impact Drivers have More Accessory Options

The last key difference between a screwdriver and an impact driver is that the latter has far more accessory options. Impact drivers are compatible with a wide range of bits, sockets, and accessories, which you can use to drive screws or bolts in tight spaces or at awkward angles. This makes them perfect for those tricky jobs which require a little extra finesse.

Frequently Asked Questions

Q: Do I need an impact wrench or driver when working on a DIY project?

If you’re taking on a DIY project, an impact wrench or driver might be incredibly useful! Not only can they help you work faster, saving you time and energy, but they can also make tough jobs much easier. Furthermore, as these tools are electric powered, you don’t have to worry about overworking your hands—and since high-quality models feature adjustable speeds and torque settings you can easily find the best intensity for each job.

Q: Are impact drivers more powerful than screwdrivers?

It’s an interesting question that many DIYers often ponder. Well, the truth is impact drivers are more powerful than screwdrivers since they can give your fastener a good jolt of torque! This comes in handy when you’re dealing with stubborn fasteners where traditional manual power just doesn’t cut it. Even better, that extra tight grip ensures that your assembled project holds firm over time.

Q: Are impact drivers safer than screwdrivers?

Impact drivers are certainly safer than screwdrivers regarding projects and repairs around the house. They are designed to tighten screws, bolts, and other fasteners with ease while significantly reducing the risk of shearing or over-tightening that can occur with a standard screwdriver. In addition, impact drivers offer enough torque to drive long, hardened screws through dense materials without stressing the user’s wrists.

Q: Why should I choose an impact driver over a standard screwdriver?

If you’re tired of struggling to get that last screw in place or noticing that your screwdriver isn’t up for the challenge anymore, then an impact driver may be the solution for you. Impact drivers are specially designed with a combination of rotation and concussive force. From forward and reverse hammering pushes – that significantly reduce the torque needed to install screws. This means no more wrist-wrenching struggles over stubborn screws!

Final Words: Screwdriver vs Impact Driver

Choosing between a screwdriver and an impact driver can be a difficult decision. The key lies in understanding each tool’s function and determining which is best suited for each job. Generally speaking, screwdrivers are ideal for lighter jobs such as tightening screws. While impact drivers are better for heavier applications like driving lag bolts or deck screws into wood. When it comes to precision and accuracy, however, screwdrivers are the clear winner since their lower torque settings prevent over tightening of fasteners. Ultimately, when it comes to choosing between these two tools, the choice is up to you. The type of job you need to do and your personal preference will likely determine which tool is the right fit.