Do you want to learn practical tips and tricks for safely and efficiently using a circular saw? The circular saw is a versatile and effective tool that is now a mainstay in the toolboxes of both expert craftsmen and DIY enthusiasts. It is an essential piece of equipment for various tasks due to its ability to accurately and efficiently cut through diverse materials, including plastic, wood, and metal. But more than simply being familiar with how the circular saw works are needed to master it.

When utilizing this powerful instrument to realize its potential and obtain the best outcomes fully, you must know the various tips and tricks that may improve efficiency, safety, and accuracy. In this article, We’ll go into a range of insightful tips and tricks that will enable you to get the most out of your circular saw’s functionality and usefulness. These tips will help you improve your cutting skills regardless of whether you are a beginner interested to learn or an expert trying to polish your techniques. Keep reading to learn more!

What Is a Circular Saw?

A circular saw is a powerful tool that may cut straight lines in various materials, including masonry, metal, plastic, and wood. It is made of a flat, circular blade with pointed teeth set on an arbor wired to a motor. When it comes into touch with the material, the blade’s quick rotation allows it to cut through it.

Circular saws are adaptable instruments often used in DIY, woodworking, and building applications. They come in various sizes, from tiny portable devices to bigger, fixed ones. Typically, a handheld circular saw has a handle on top and a base plate or shoe that sits on the material cut on the bottom. They may be modified to create cuts, such as straight, angle, and miter.

Blades for circular saws are created for specific cutting tasks and materials. While blades with fewer teeth are superior for tearing through heavy timber, those with more teeth produce smoother cuts in materials like plywood. There are also specialist blades available for cutting metals, polymers, and other materials.

When using a circular saw, safety measures should be followed, including donning gloves, safety goggles, & ear protection, as well as ensuring the blade guard is operating well and securing the workpiece before cutting. For the circular saw to be used safely and effectively, adhering to the manufacturer’s directions and recommendations is crucial.

Types of Circular Saw

Circular saws come in two primary varieties, sidewinder circular saws & worm-drive circular saws. The location of the motor between the blade and the gear is the primary distinction between these models.

⚙️Sidewinder Circular Saw

The sidewinder circular saw employs a motor formally referred to as “a spur gear,” which means that it is in line with its blade, as you can see in the photo, and provides the blade with mighty power of up to six hundred RPM. The blade of the sidewinder circular saw is also on the right. Depending on your desire, the sidewinder circular saw might have the blade on the right or left side.

⚙️Worm Drive Circular Saw

The worm drive circular saw’s motor is located behind the blade, and a system of gears transmits the engine’s rotational force to the blade. This has benefits and drawbacks; on the one hand, it reduces the blade’s peak speed, which may be 4500 RPM, but on the other, it raises the torque. The blade of almost every worm drive circular saw is on the left side. The shoe is thicker and weighs more than the sidewinder circular saw. You may encounter one variety more frequently than another if you reside on the west coast.

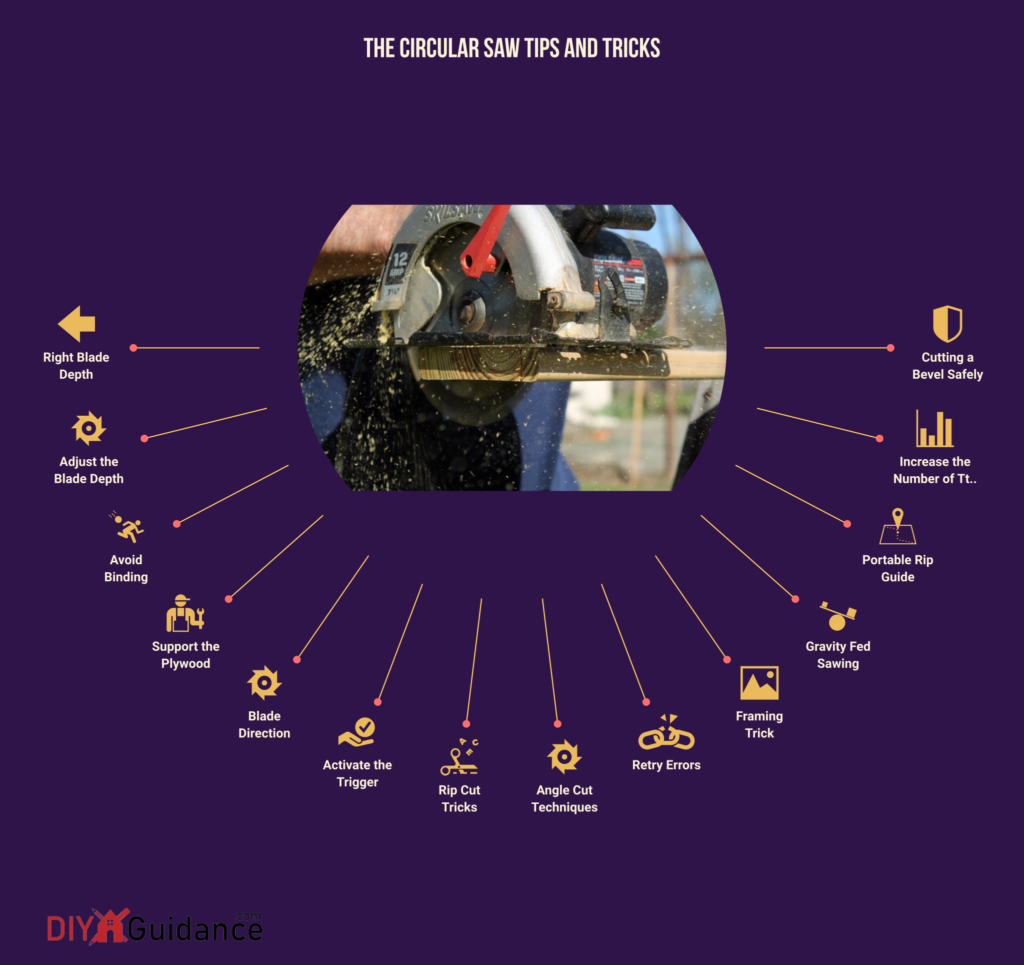

The Circular Saw Tips and Tricks

Learn the proper techniques for using a circular saw. Using these expert tips and tricks, you can build anything, from a few cabinets and other furniture works to a whole home, quicker and better.

➣Right Blade Depth

Several issues arise when the blade is set too deeply. First off, since more of the blade is visible during cutting, it’s riskier than a blade that has been properly adjusted. Furthermore, the saw is more likely to bind and kick back if the blade is too deep. Putting safety concerns aside, correctly adjusted blades cut more effectively.

➣Adjust the Blade Depth

Before you press the cutting trigger, adjust the blade depth. You can measure the blade depth by disconnecting the saw and holding it next to the board with the blade guard retracted. Once the blade is approximately 1/4 to 1/2 inch below the board, release the depth-adjustment lever or knob & pivot the saw base. When the lever and knob are tight, you may start cutting.

➣Avoid Binding

Ensure the board end you cut is never restricted from falling or moving. Let the cut end fall while making rough cuts in framing timber. But as the cut gets closer to finishing, be cautious that the falling part can take a piece of wood with it. When cutting boards for fancier projects, keep the board continually to prevent splintering. The cutoff component should not be clamped, held, or otherwise restricted.

➣Support the Plywood

The plywood veneer may break or split when the cutoff piece lowers when the plywood is crosscut without being supported throughout its whole length. Span your sawhorses with two 2x4s if you’re utilizing them. This will provide the necessary help.

➣Blade Direction

The blade of a typical circular saw used for cutting wood is raised from the material while it is being cut. The direction indication on the circular saw’s guard and the saw blade may be used to determine which way to attach the blade. Due to the blade’s orientation (often blade-left saws), certain blades will have their labels attached to the inside of the saw.

➣Activate the Trigger

A two-stage trigger is common in circular saws. You must either push up or push down the safety button while pressing the trigger when it is within your thumb’s reach. A power button may also be included on certain battery-operated saws, which you must push before the trigger becomes operational.

➣Rip Cut Tricks

A table saw is often better than a circular saw for ripping timber. However, a circular saw will suffice if you don’t have a table saw on hand, and the rip cut doesn’t need accuracy. The secret is to secure the board as you shred it. Clamps will only obstruct your work if the board you are tearing is quite broad. You should tie the board to your sawhorses to avoid using a clamp. We have allowed the nails to protrude here because they don’t obstruct the saw bed. But even after driving the nails flush, you may still easily remove the board. Use finish nails to prevent damage to best-quality boards, then pull them through the back after you’re through.

➣Angle Cut Techniques

Blade guards on some more recent saws are designed to change even while you’re sawing at an angle. However, even with these more modern models, you may make an angled cut more easily if you first raise the blade guard. Release the blade guard gradually until it rests on the board a few inches into the cut. Without withdrawing the blade guard before beginning an angled cut, the guard may snag on the wood, bind the saw blade, or cause the cut to veer off course.

➣Retry Errors

It takes practice to become proficient with saws in cutting straight lines. Maintaining the saw blade on course is simple after it is positioned and cut down the line. But it’s difficult to steer the saw back to the line if you start crooked. Avoid attempting to direct the blade back to the line. Instead, halt and let the blade cease rotation. Next, remove the saw through the cut, view along the cut, and restart. You’ll become an expert at cutting straight with practice.

➣Framing Trick

It’s often simpler to cut joists and other big pieces of timber where they are rather than lifting them onto sawhorses when cutting them. Simply placing the board on the toe and leaning it against your shin is simple. Next, position the saw in line with a mark and allow gravity to guide it through the cut. Maintain the saw cut at least twelve inches away from your toe.

➣Gravity Fed Sawing

The circular saw is the ideal equipment to use if you ever need to cut a large, straight, vertical slit into a wall. Remember to cut down from the top of the wall while using the saw. You may use gravity to your advantage by letting the saw’s weight push the blade into the cut.

➣Portable Rip Guide

If you utilize your index finger as a guide, cutting long, thin rips with a circular saw is simple. Connect the blade to the line. Next, hold the saw base with your index finger and thumb while guiding the cut by letting your finger go down the board’s edge. This method is secure if you hold the saw tightly before switching it on and don’t let go until the blade stops.

➣Increase the Number of Teeth

Change your blade’s tooth count as you progress from rough cuts to final cuts. The end cut is smoother the more teeth there are. Some premium blades may give you a polish comparable to 220-grit sandpaper. Use them sparingly when necessary since they are more expensive.

➣Cutting a Bevel Safely

Every circular saw has a bevel angle adjustment range of at least forty-five degrees. On the other hand, the bottom blade guard has a propensity to snag on the edge of the board when the base plate is completely tipped over. Keep the saw from being forced if this occurs. Release the trigger, then manually elevate the blade guard before cutting. You may remove the guard after slicing the blade about an inch into the board. Check the video below to learn more about the tips and tricks of using circular saw.

Choosing A Circular Saw

You may choose your circular saw, but it’s important to know a few factors before deciding, such as the tool’s power, intended application, and accessories. Above all, taking your time and thoroughly considering your reasons for wanting to utilize a circular saw before rushing to get such a tool is crucial.

◻️Power

You should get by with 900 Watts of electricity for any little woodworking projects around the home. Over a thousand seven hundred Watts, a circular saw will enable you to cut heavy materials like metal and concrete, and firewood.

◻️Frequency

When selecting your saw, the frequency of usage is a crucial consideration. Choosing a high-end saw is not necessary if you use it sometimes. However, a skilled carpenter must choose a circular saw based on the task that has to be done.

◻️Brake System

There are two different kinds of braking systems: manual and electronic. I must first emphasize that they are both safe & secure before we discuss the differences between the two sorts. The manual system does not use current to stop the blade; instead, it only waits for the blade to stop on its own, which can take anywhere between 5 and 7 seconds. The electric brake system utilizes the electric current supplied to the circular saw to stop the blade, and it does so in just 2 seconds.

How Do Circular Saws Operate?

◾️Ensure that the blade is sharp & appropriate for the task at hand to get a clean output;

◾️Adjust your cut’s depth so that it is about 5 mm greater than the wood’s thickness;

◾️Making the workpiece stationary using clamps or a vise will prevent it from moving or vibrating while being cut. But once again, begin to make sure the saw won’t run into any obstructions while cutting;

◾️Turn on the saw while holding it in both hands and wait for the blade to spin fully;

◾️Move gently while placing the saw’s nose on the cutting line. Regular progress checks should be made; there should be no early pressure. Time must be given to ensure that the machine gets a proper cut.

◾️The finished cutting will then be evident by the material dropping to the ground. After that, the user’s safety will be ensured by replacing the protective cover.

◾️It is gripped in two hands and provides superb balance during cutting due to a wide handle at the back and another at the front;

◾️Some circular saws are equipped with a laser guide that allows you to produce flawless cuts that may make your work simpler;

Circular Saw Safety Measures

Powerful power tools include the circular saw. This makes it risky equipment that should only be used with a few safety measures to ensure cautious, secure work. You must utilize it while wearing safety gear to protect yourself. In addition, even though certain models of circular saws have an integrated dust blower, using this instrument might result in a lot of dust; therefore, you must protect yourself by wearing a mask or a set of safety glasses.

Before using your saw, be sure to:

◾️Verify the stability of the workstation or sawhorse you have.

◾️Make sure your blade is properly secured as well.

◾️With both hands, firmly grasp the saw.

◾️Before cutting, let your circular saw run at its fastest.

◾️Keep electrical lines away from where you are cutting;

◾️Avoid applying excessive pressure to your saw;

◾️Wear all necessary safety gear, including gloves, a dust mask, glasses, and hearing protection.

◾️Select a circular saw featuring a laser guide for even cleaner, more accurate, and straighter cutting.

◾️Before setting the saw down, give it a full stop.

What to Look For in a Circular Saw Features

There are many important characteristics to consider while shopping for a circular saw. These factors will determine the saw’s effectiveness, adaptability, and user-friendliness. The following are some important matters to consider:

👉Grip

A saw’s balance, ease of adjustment, and grip feel all contribute to the user’s first impression of the tool. For a secure grip, every circular saw must have a rubberized surface on the back of the handle. Most of the front knobs (pommels) will also be made of the same material. We haven’t encountered a circular saw with a truly bad grip. For our tastes, some, however, can have a front handle that is too close to the back handle.

👉Safety

Trigger safeties were a common topic of discussion as we compared the top circular saws. Some of those trigger safety buttons were challenging for us to press. Some people appeared to be too high up on the handle. Trigger safeties should typically be within your thumb’s reach. You should have no trouble reaching safety, even using a bevel cut.

We also favored the trigger safety buttons that you depressed. Anything that requires pushing in slows you down. More so than pulling downward, repositioning a hand to squeeze the thumb inward puts your grasp at risk.

Last but not least, we detest saws that demand you shift your finger to access the trigger safely. After you start the saw, you don’t want to have to move your hand again. This only makes using the gadget awkward at first.

👉Depth Adjustments

Pro-quality circular saws should make adjusting the depth of the cut simple. Depth scales frequently need to be corrected. Before making any precise cuts, check them first. Since you can write your markers or use a blade as a depth measure, that’s rarely a deal-breaker for us.

👉Weight

Even with adequate balance, a hefty saw will always feel heavy. A perfectly balanced saw lessens the effort required to use a heavy instrument. Just ask anyone who prefers a worm drive or rear handle saw. Remember that cordless circular saws are at their heaviest when powered by the plus-size batteries we frequently use. Larger batteries could compromise the tool’s balance from its original design.

Frequently Asked Questions

What matters most while using a circular saw?

Circular saws are made easier to operate by precise cutline indications, a smooth retraction guard, great blade visibility, and a flat shoe parallel to the blade. The optimum cutline indications line up exactly with the kerf the saw made. You should be able to insert a thin saw blade inside the opening you wish to make.

What is the circular saw’s first usage rule?

What must you do before using a circular saw to cut something? Put on safety glasses, goggles, and a face shield and pair them with the appropriate eye protection. Wear a certified respirator or dust mask when exposed to dangerous or bothersome dust. In noisy settings, wear the proper hearing protection.

Could a beginner utilize a circular saw?

Beginners may quickly pick up the skills necessary to use a circular saw safely and effectively. But if handled correctly, it may be safe, just like any power instrument. In Step 5, you may learn more about circular saw safety.

Do circular saws better than jigsaws?

Although a jigsaw can be used for most of the activities that a circular saw can carry out, including straight cuts & cuts on a tilt, the occupations such as kitchen fitting & joinery that have a frequent requirement for complicated cuts truly make use of the tool’s capabilities.

Why do circular saw blades work well?

Blades with more teeth often produce a cleaner, smoother cut, whereas a rougher finish would result from fewer teeth. Many individuals often choose a 24-tooth circular saw blade while cutting metal, especially when cross-cutting timber and sheet materials.

Final Words

Knowing fundamental circular saw tips and tricks is key to precision and efficiency in DIY projects. The circular saw is a flexible and useful instrument that may significantly improve your woodworking and building projects, but it needs ability and understanding to use it correctly. Increase accuracy and productivity in your job by applying the following tips and tricks. You may master the circular saw and advance your abilities in construction and woodworking with time, practice, and a commitment to safety. Do you want to learn how to use cutting saw with wood? Click Here!